Obtenga muestra gratuita

El polímero superabsorbente (en adelante, SAP) es un nuevo tipo de material polimérico funcional. Como material absorbente, puede absorber cientos o miles de veces su peso y convertirse en un hidrogel expandible. El hidrogel tiene la capacidad de retener el agua incluso bajo presión. Es muy diferente de otros materiales absorbentes de agua tradicionales, como el papel tisú, el algodón, la esponja y la pulpa de celulosa. ¿Cuál es la historia del SAP?

En la década de 1980, los materiales absorbentes de agua eran el papel tisú, el algodón, la esponja y la pulpa de celulosa. La capacidad de retención de agua de estos materiales es de solo 20 veces su peso, como máximo.

En la década de 1960, el Departamento de Agricultura de Estados Unidos comenzó a trabajar en materiales para mejorar la conservación del agua en los suelos. Desarrollaron una resina basada en el injerto de polímero de acrilonitrilo sobre la estructura principal de las moléculas de almidón. Este nuevo material absorbente puede absorber más de 400 veces su peso. Lo más importante es que el gel no liberó agua líquida ni siquiera bajo presión.

Como las empresas japonesas fueron excluidas por el USDA, comenzaron una investigación independiente utilizando almidón, carboximetilcelulosa (CMC), ácido acrílico, alcohol polivinílico (PVA) y anhídrido maleico de isobutileno (IMA).

En la década de 1970, se utilizó comercialmente por primera vez un polvo que absorbe agua para productos higiénicos desechables (no para aplicaciones de enmiendas del suelo como se pretendía originalmente).

SAP se utilizó por primera vez en Europa en un pañal para bebés en 1982. Poco después, UniCharm introdujo pañales súper absorbentes para bebés en Japón.

Con el paso de los años, la tecnología ha avanzado tanto que prácticamente no se utilizan polímeros absorbentes de humedad injertados con almidón en productos higiénicos desechables. Estos superabsorbentes suelen ser homopolímeros acrílicos reticulados (generalmente neutralizados con sodio).

Los superabsorbentes utilizados en aplicaciones de enmiendas del suelo tienden a ser copolímeros de acrilamida-acrílico reticulados (generalmente neutralizados con potasio).

El polvo absorbente de agua suele referirse a una clase de sustancias en polvo altamente absorbentes que se utilizan en una amplia gama de aplicaciones gracias a sus propiedades higroscópicas altamente eficientes. Absorben y retienen rápidamente la humedad del entorno, previniendo eficazmente la humedad, el moho o controlando la humedad.

Los productos químicos absorbentes de agua, también conocidos como hidrogeles o superabsorbentes, son materiales especializados diseñados para capturar y retener eficazmente grandes volúmenes de agua. Los productos químicos absorbentes de agua, comúnmente conocidos como hidrogeles o polímeros superabsorbentes, son compuestos especializados capaces de absorber y retener grandes cantidades de agua.

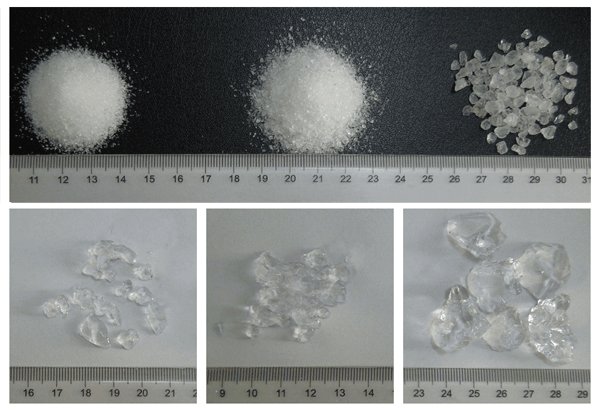

El polvo absorbente de agua , también conocido como polvo retenedor de agua o polvo súper absorbente , es un tipo de material capaz de absorber y retener grandes cantidades de agua, generalmente muchas veces su propio peso.

El polvo superabsorbente es un material especializado de alto rendimiento capaz de absorber y retener cantidades extremadamente grandes de líquido, a menudo hasta cientos de veces su propio peso. Los materiales absorbentes son sustancias capaces de absorber y retener líquidos, gases u otros fluidos.

Contamos con un servicio en línea de "Preguntas al Experto" disponible las 24 horas. Si tiene alguna pregunta, contáctenos.